-

What is an L.E.D?

-

What is the advantages of L.E.D?

-

How does LED work?

-

In what types of projects can you use LED strips or neon flex?

-

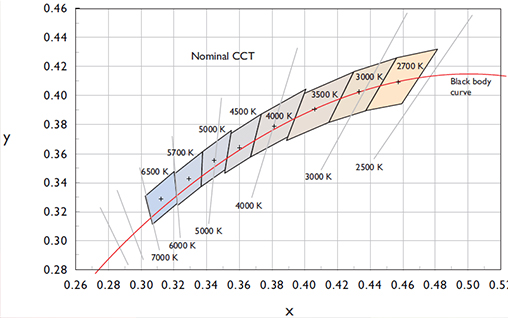

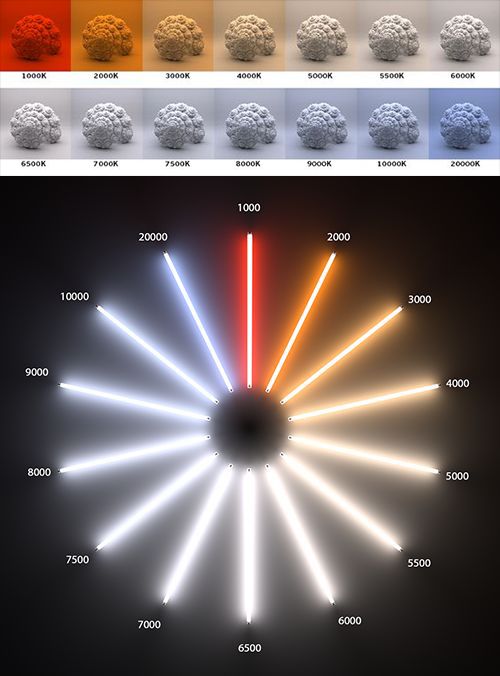

What correlated color temperatures are available for LED strip lights?

-

What is RGB, RGBW, RGBA and RGBCCT?

-

What waterproof resistance ratings are available for LED strip lights?

-

How can LED strip lights be soldered?

-

What is the process for trimming LED strip lights?

-

How can you adjust the brightness or color of LED strip lights?

-

How should LED strip lights be installed?

-

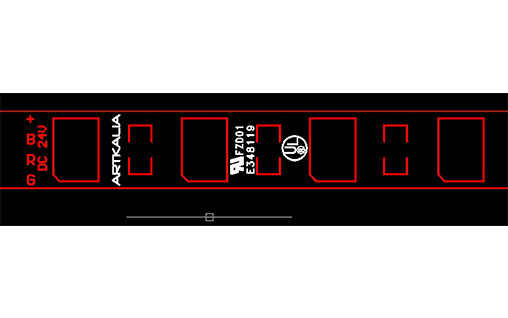

Can FINELED design a PCB board with the customer's logo?

-

How do you ensure consistent color temperature uniformity in your products?

-

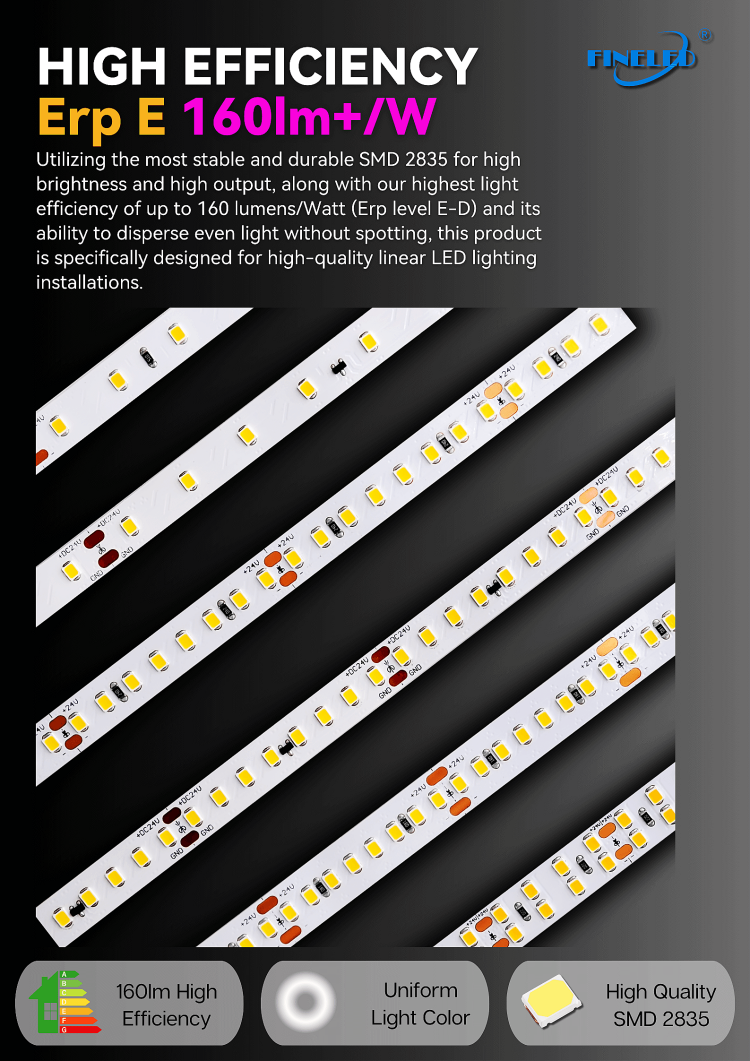

Which LED chip do we use?

-

What defines high efficiency in LED strip lights?

-

Which certificates do we possess?

-

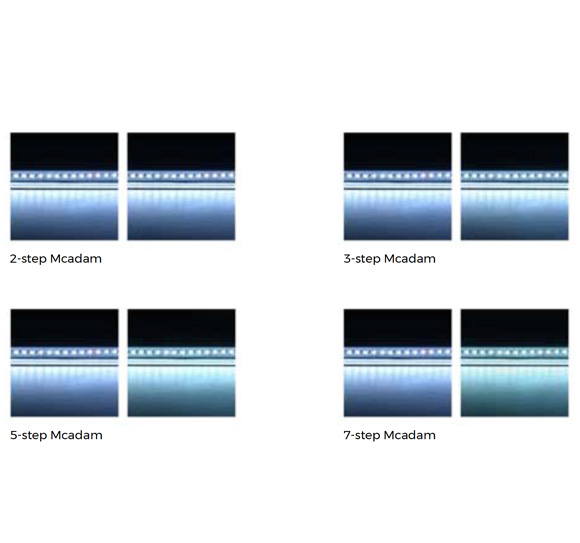

What is the meaning of SDCM?

-

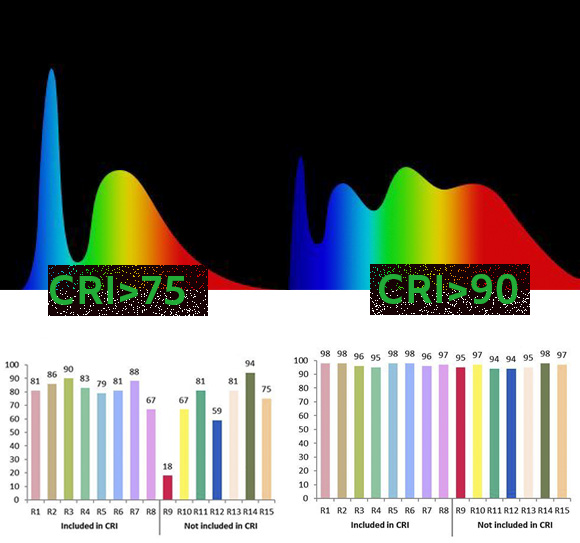

What is the Color Rendering Index (CRI) of FINELED LIGHTING's products?

-

What should you consider when selecting high-quality LED strip lights?

In the simplest terms, a light-emitting diode (LED) is a semiconductor device that emits light when an electric current is passed through it. Light is produced when the particles that carry the current (known as electrons and holes) combine together within the semiconductor material. Since light is generated within the solid semiconductor material, LEDs are described as solid-state devices. The term solid-state lighting, which also encompasses organic LEDs (OLEDs), distinguishes this lighting technology from other sources that use heated filaments (incandescent and tungsten halogen lamps) or gas discharge (fluorescent lamps).

LED (Light Emitting Diodes) lights are the latest and most fascinating technological advancement in the lighting industry. LEDs are small, solid light bulbs that are powerful, energy-efficient, and long lasting. LEDs operate in different ways than traditional incandescent bulbs. This makes LEDs far more durable than traditional incandescent light bulbs. LED technology also provides many additional advantages over incandescent, fluorescents, and compact fluorescent lamps and lighting devices. This includes an exceptionally longer lifespan (60,000 hours), significantly lower energy consumption (90% more efficient), reduced maintenance costs, and higher safety.

You certainly hear and read a lot about the benefits associated with the energy efficiency of LED light emitting diodes versus traditional lighting. When you compare them to other energy-saving illumination methods that are currently available, you will find that LED lamps are definitely the smartest and most power-saving solution for illumination. The top 8 benefits of using LED lights over their less efficient alternatives can be read below.

Efficiency

LEDs are packed powerfully with sufficient energy and use up to 90% less power than incandescent light bulbs.

Longevity

LEDs have a lifespan of up to 60,000 hours as opposed to 1,500 hours typical of incandescent bulbs.

Sturdiness

LEDs are solid express lighting devices that utilize semiconductor material rather than a filament or neon gas.

Safety

Superior safety may be the most significant benefit of LEDs. LED lamps generate almost no warmth therefore they are cool to the touch and can be left on for hours without incident or consequence if touched, no glass, no UV and IR, no mercury and so on.

Environment

LEDs are made of non-toxic materials, unlike neon lighting that use mercury that may pose a danger to the environment. LED is recyclable and also considered “green”, or earth-friendly.

Color

LED lighting are offered in a variety of base colors, such as red, blue, and amber. Due to the fact that traditional incandescent bulbs use filters to produce colors, they are extremely bad. LEDs can be mixed together to produce large numbers of color options.

Long-term

LEDs are poised to replace traditional incandescent lights. LEDs are rapidly, without a doubt, becoming the preferred lighting solution of both homes and offices. long-lasting life up to 50,00 hours.

Uses

LEDs are currently used for a wide variety of different applications, such as in residential lighting, the military, as well as the architectural, automotive, transmissions, electronic instrumentation, the entertainment and gaming, the military, and the traffic and transportation industry. Since LEDs are focused lights, they are great at performing some specific lighting tasks, such as desk lamps, reading lights, night lights, security signals, spotlights, accent lamps, and lighting for signs.

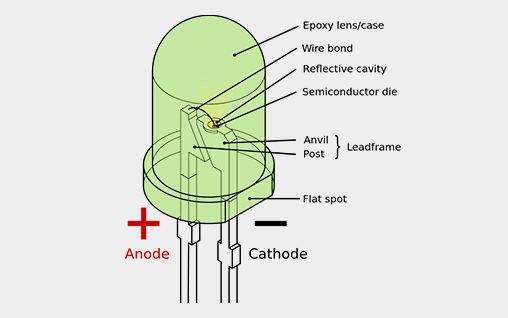

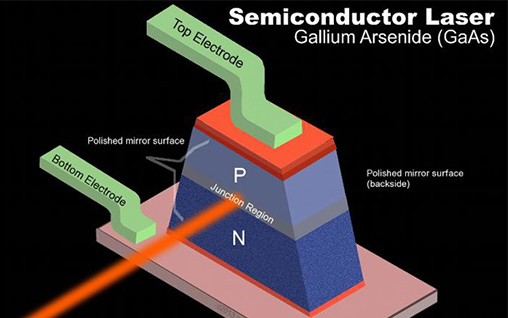

LEDs create light

by electroluminescence in a semiconductor material.

Electroluminescence is the phenomenon of a material emitting light when

electric current or an electric field is passed through it - this happens when

electrons are sent through the material and fill electron holes. An electron

hole exists where an atom lacks electrons (negatively charged) and

therefore has a positive charge. Semiconductor materials like germanium or

silicon can be "doped" to create and control the number of electron

holes. Doping is the adding of other elements to the

semiconductor material to change its properties. By doping a semiconductor you

can make two separate types of semiconductors in the same crystal. The boundary

between the two types is called a p-n junction. The junction only allows

current to pass through it one way, this is why they are used as diodes. LEDs

are made using p-n junctions. As electrons pass through one crystal to the

other they fill electron holes. They emit photons (light).

The P-N junction

is the basis of the functioning of the LED. The LED has an anode and a cathode

separated by a crystal of semiconductor material. Addition of impurities to the

semiconductor material produces P-N junctions within the chip. The entire

assembly is within a plastic cover that can also double up as a lens to guide

the light emitted by the LED.

Phosphors are used to help filter the light output of the LED. They create a more pure "harsh" color. Engineers had to figure out how to control the angle the light escapes the semiconductor, this "light cone" is very narrow. They figured out how to make light refract or bounce off all surfaces of the semiconductor crystal to intensify the light output. This is why LED displays traditionally have been best viewed from one angle.

LED lights, including our flexible LED strips and neon flex, offer versatile applications across a wide range of settings such as architectural, office, retail, hotel, home, hospital, heritage, and landscape environments. In fact, LED strip lights can be found in nearly every imaginable space.For additional product details, please visit http://www.fine-led.com/index.php?s=/sys/cate/12.html

FINELED offers a range of standard color temperatures, including 1800K, 2200K, 2600K, 3000K, 4000K, and 6000K for white CCTs. We also provide single-color options such as Red, Green, Blue, Yellow, Pink, Ice Blue, and Golden Yellow. Additionally, we offer dynamic color-adjustable options ranging from 2700K to 6000K, as well as color-changing options like RGB, RGBW, RGBWW, and RGBA, among others...

More color temperature and details, please view http://www.fine-led.com/index.php?s=/sys/cate/12.html

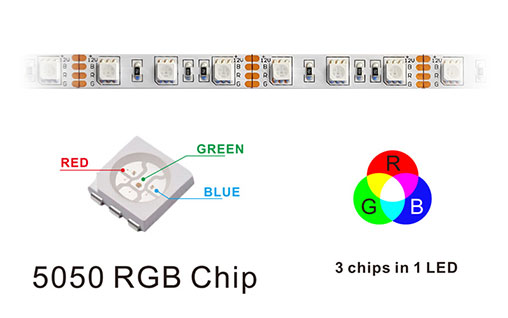

RGB:

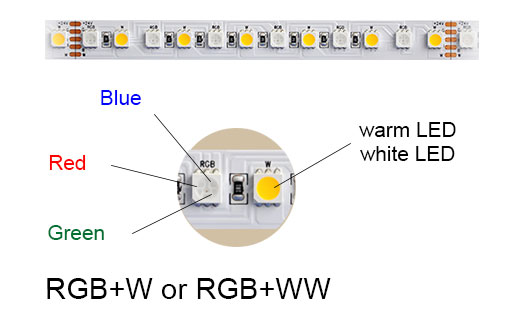

Standard RGB LED strip uses a 3-in-1 LED chip made up of red, green and blue chips. It can produce a wide range of colours by mixing the three and looks almost white with all three at full brightness. RGB+W LED strip uses either a 4-in-1 LED chip that has a white chip as well as red, green and blue or an RGB chip alongside a white chip.

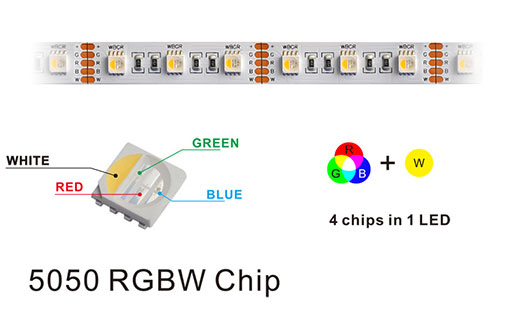

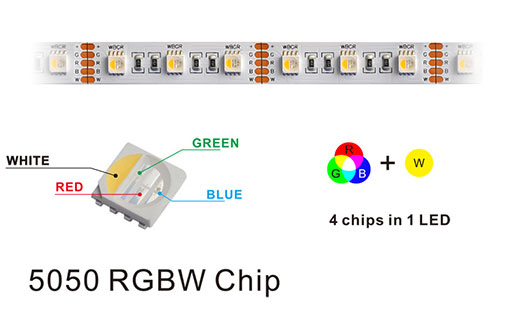

RGBW:

Fixtures with red, green, blue and white LEDs create vivid (warm white or cold white), bright colors. RGBW fixtures project a cool shade of white and are ideal for color mixing pastels. Add white to any standard color and adjust the saturation to achieve your client’s desired shade. In addition to creating pastels, white LEDs can be used independently so you do not have to mix colors to achieve it. Choosing the right LED combination depends on your gigs and the colors you want to achieve. Before you make your purchase, do some homework and check your books to see what colors received the most requests, ask your fellow DJ friends about their client’s requests or log onto a DJ forum and conduct your own poll. Both combinations create an enormous amount of colors — deciding on the shade of those colors is where your expertise comes in.

RGBA:

Fixtures with red, green, blue and amber LEDs create warm, rich colors. RGBA fixtures project a warm shade of white and exceptionally rich shades of gold, yellow and orange. Additionally, adding amber to standard colors broadens the color spectrum. Amber LEDs are a major benefit to RGBA fixtures because it is difficult to achieve the amber color through color mixing.

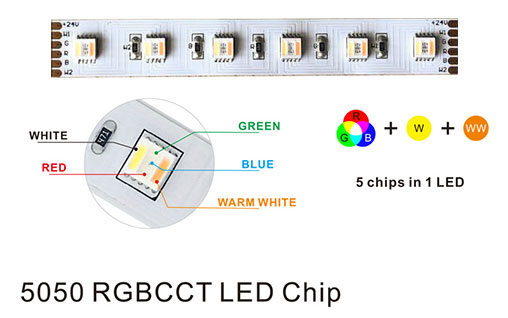

RGBCCT:

We can call also RGBWW, ingetrating RGB and warm white LED and White LED to one 5-in-1 LED creates better-quality color temperature adjustment 27600-6500K compared to RGBW, The RGBCCT led strip light is an upgraded version of the RGBW led strip. It does not have a fixed color temperature like white color light in RGBW led strip, but has two color temperature led chips, a warm white in 2600K, and a white color light in 6500K,which makes the color temperature selection in the lighting application scene more flexible. It also have RGB color changing tegher to reaches amazing lighting effect to designer.

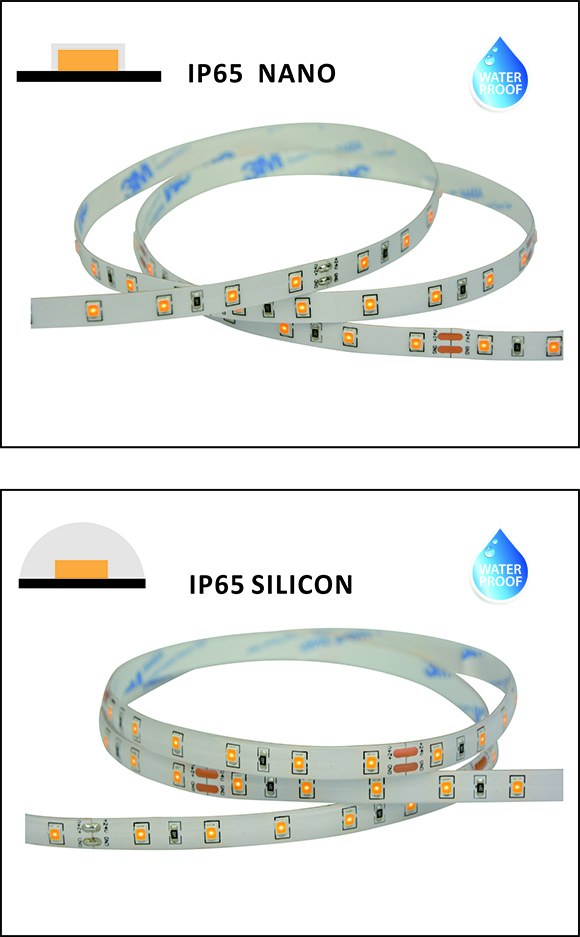

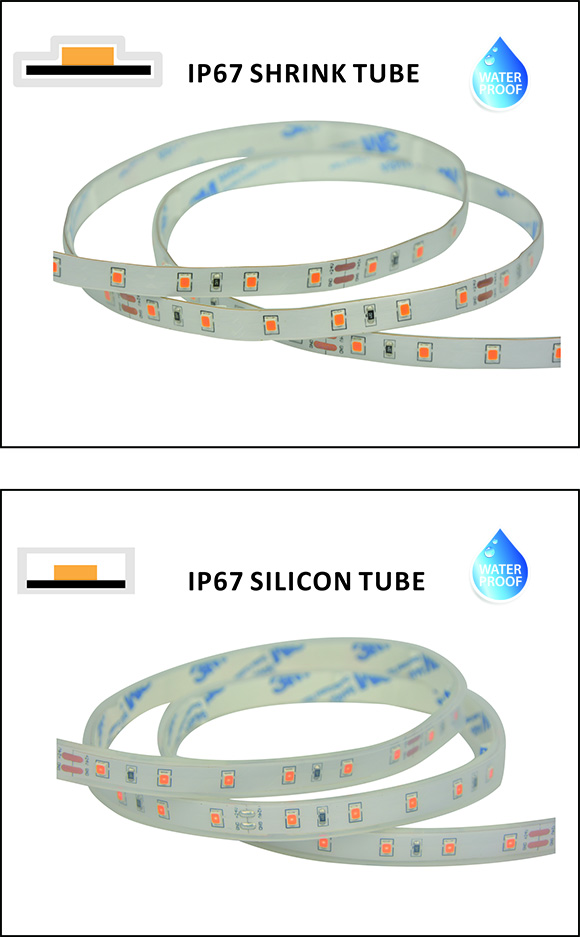

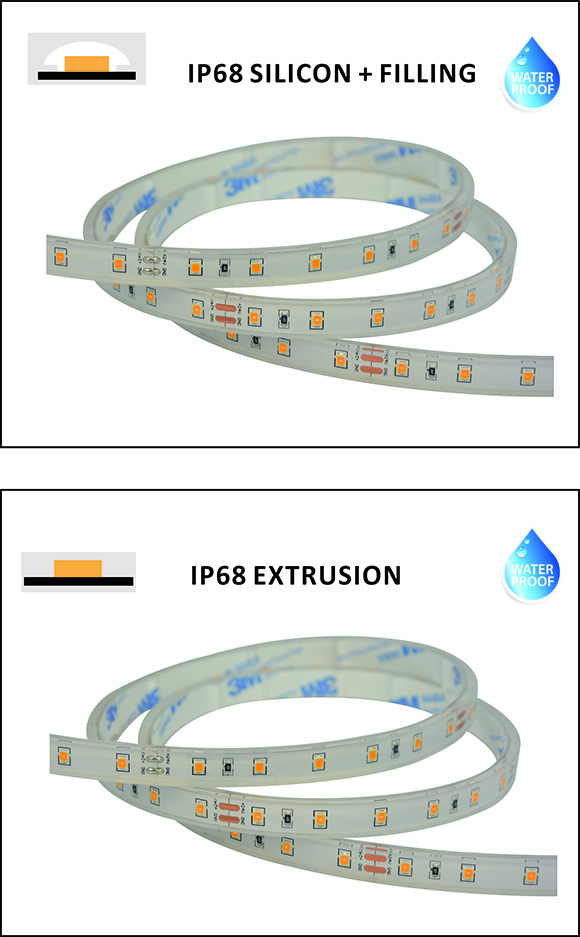

FINELED provides various waterproof resistance options for LED strip lights, including non-waterproof IP20, IP65 with silicon coating(SC), IP65 with Nano coating (NA), IP67 with silicon tube(ST1), IP67 with shrink tube(ST2), IP68 with full extrusion hollow(ET), and IP68 with full extrusion filling (EF), among others.

Feel free to consult our professional sales team, and they can recommend a suitable waterproof LED strip based on your specific application environment.

You can ask us which environment you want to apply and a reasonable waterproof LED strip will be recommended by our professional sales.

More types of waterproof LED strips, pls view http://www.fine-led.com/index.php?s=/sys/list/110.html.

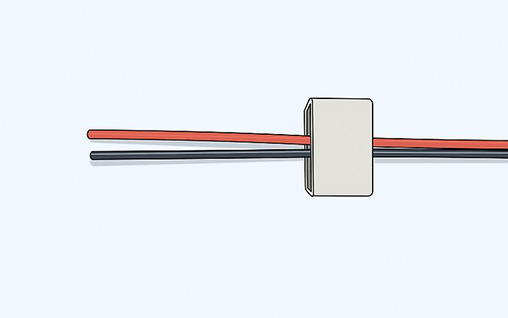

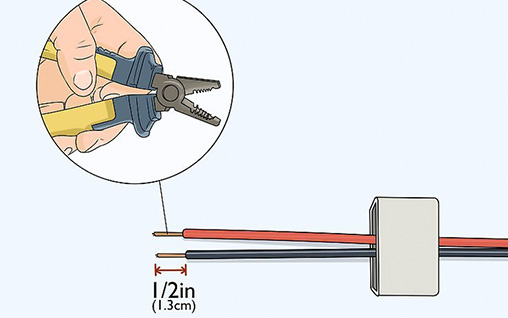

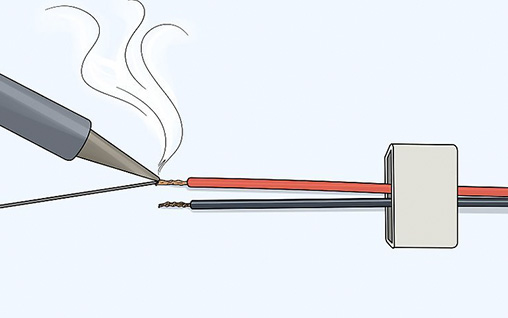

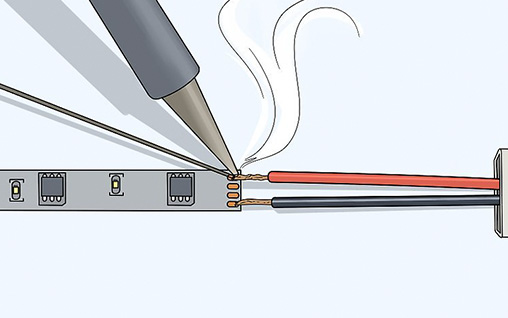

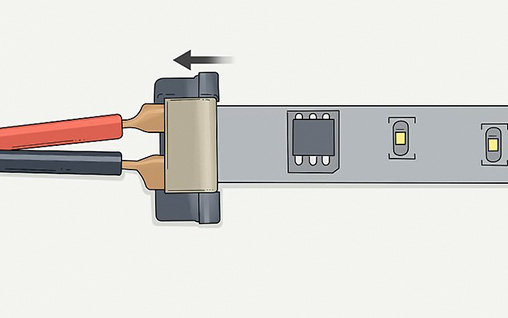

At times, it becomes necessary to solder an LED light strip or create a joint connection between two LED light strips. The following steps will guide you through the process.

-

1 Cut the silicon cover together with the copper dots of LED light strip

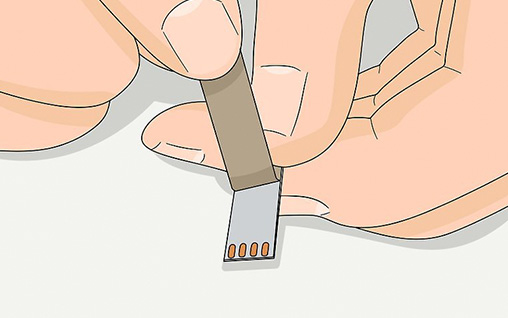

- 2 Cut the wires to length and slide them through the head cap

- 3 Strip the wires with wire strippers

- 4 Twist and coat each wire end with solder

- 5 Solder the wires to the LED light strip

- 6 Glue a silicone end cap onto the LED light strip and sealed

- 7 Finished

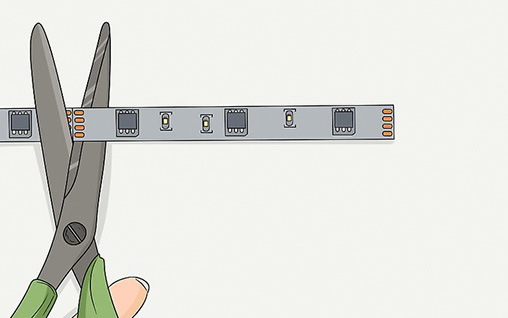

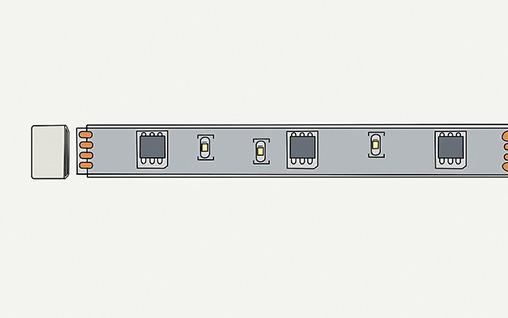

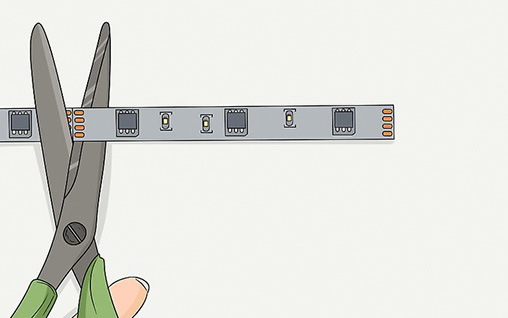

Cutting LED strip lights is a straightforward process and can be done with a pair of scissors. Each segment of the LED strip typically has a pair of copper dots at the end. Simply cut between these dots to ensure the remaining LEDs function properly. After cutting, you can connect the LED strips to a power source using either a quick connector or by soldering the connections. When connected correctly, the LEDs should illuminate with a vibrant display of colors.

- 1 Cutting Apart LED Strips

- 2 Locate the cut line marked by the copper dots on the LED strip. Use scissors to cut the strip apart, ensuring you cut between the copper dots. Align the cut carefully to avoid damaging the LEDs.

- 3 Peel back the LED’s adhesive backing 1⁄4 in (0.64 cm).

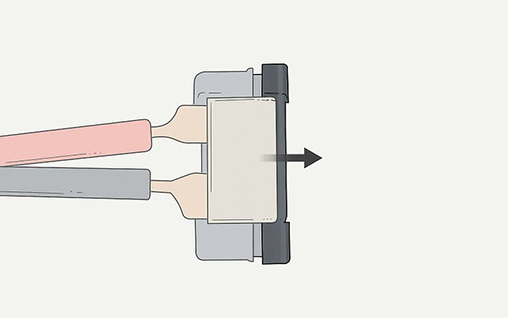

- 4 Pull the plastic bar 1⁄8 in (0.32 cm) off of the quick connector.

- 5 Align the quick connector with the LED strip and Close the plastic bar on the quick connector.

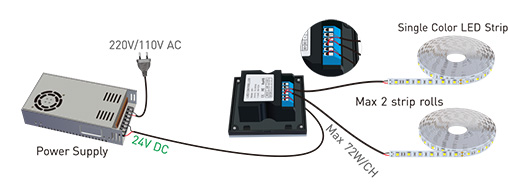

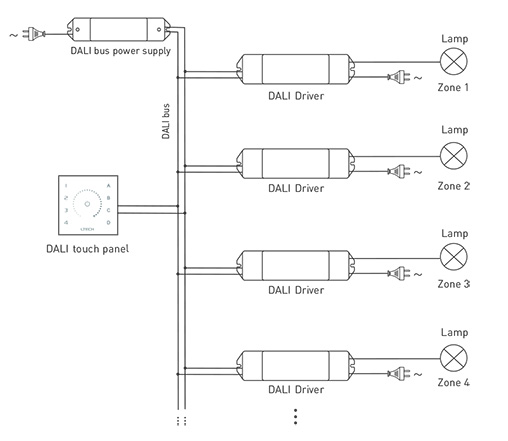

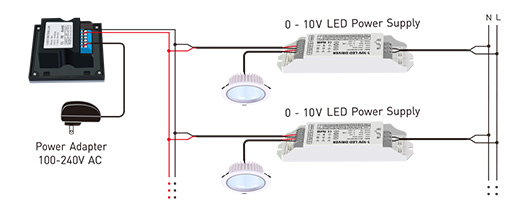

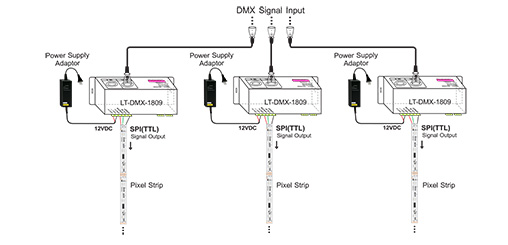

There are several methods to dim LED strip lights, including PWM, DALI, 0/1-10V, and DMX512. The choice of method depends on your lighting design and wiring layout, so you'll need to consider these factors based on your existing setup.

- PMW

- DALI

- 0/1-10V

- DMX512

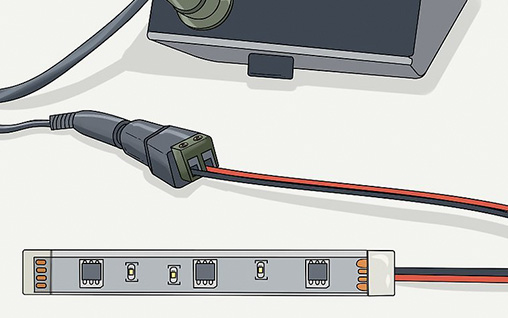

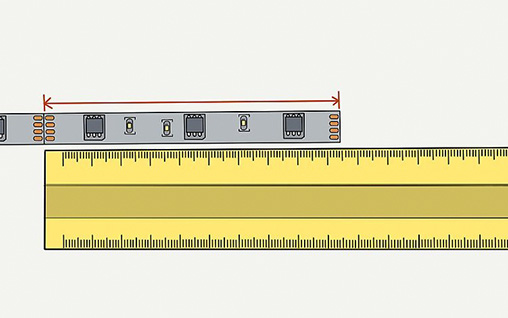

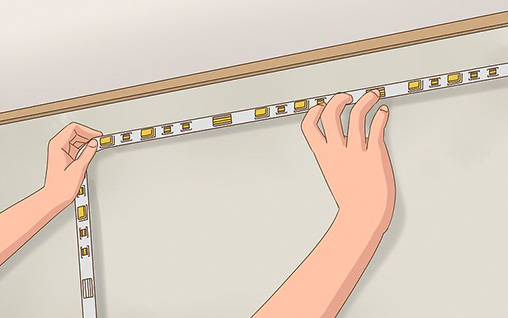

If you want to add color or ambiance to spaces like a room, kitchen, cabinet, bedroom, or bathroom, LEDs are an excellent choice. LED strips come in large rolls and are easy to install, even for those without electrical experience. A successful installation requires a bit of initial planning to ensure you get the correct length of LED strips and a matching power supply. You can connect the LED strips using purchased connectors or by soldering them. Connectors are easier to use, but soldering provides a more permanent and secure connection. Finally, stick the LED strips in place using their adhesive backing, then plug them in to enjoy the enhanced ambiance.

- 1. Measure the area where you plan to install the LEDs.

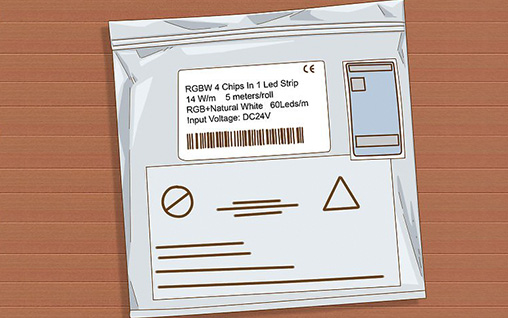

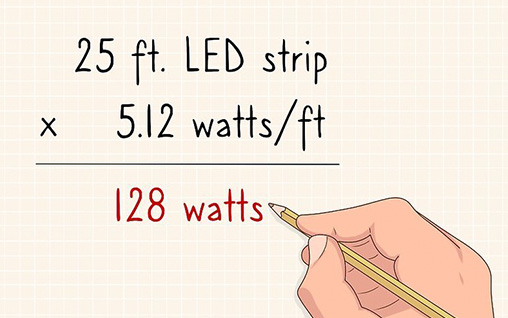

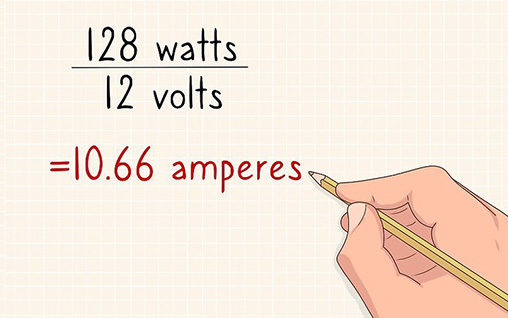

- 2. Check the LED strips to determine their required voltage, current, and power by examining the product label on the roll package. The label will indicate whether the voltage is 12V or 24V and specify the power consumption per meter or per five meters. Use this information to calculate the total power consumption needed for your power supply. To ensure reliable operation, select a power supply that provides 15% more power than your calculated requirement. This accounts for typical electrical wastage in wiring and the power supply itself. Divide the total power consumption by the voltage to find the minimum amperage required. Choose a power supply that meets or exceeds these power and amperage specifications.

- For example, if a one-meter LED light strip consumes 14.4W, then a 5-meter strip will consume 14.4W × 5 = 72W. To account for electrical wastage, add 15% to this value: 72W × 1.15 = 82.8W. Divide the total power requirement by the voltage to find the minimum amperage needed: For a 12V power supply: 82.8W ÷ 12V = 6.9A For a 24V power supply: 82.8W ÷ 24V = 3.45A Therefore, you need a power supply that provides at least 12V/6.9A or 24V/3.45A.

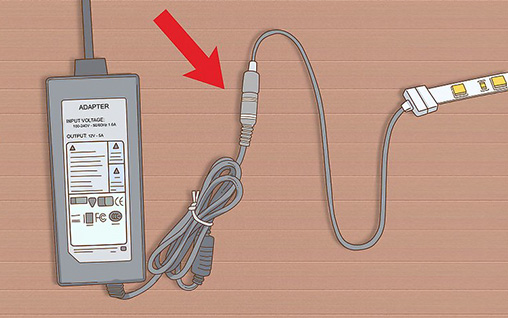

- 3. Connecting LED Strips and Power Supplies.

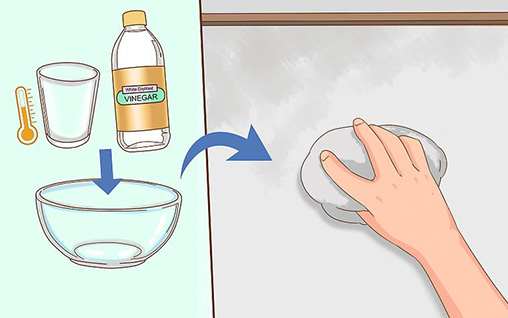

- 4. lean the installation surface with warm water, then wipe it dry to prepare for sticking.

- 5.Then, peel off the adhesive backing and press the LEDs into place.

Certainly, we have a highly skilled team of engineers specializing in this area. We excel in designing PCBs tailored to customer specifications and can incorporate logos, CE markings, UL numbers, or any other desired elements. We welcome OEM and ODM orders from customers worldwide.

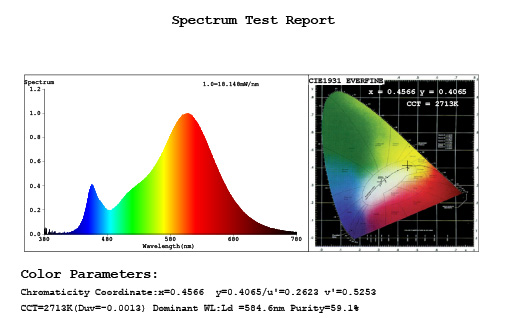

FINELED performs rigorous inspections to ensure consistent color temperatures in every batch of customer orders. We carefully monitor this process starting from the initial raw material assessment, utilizing spectroscopic machines and microscopes..

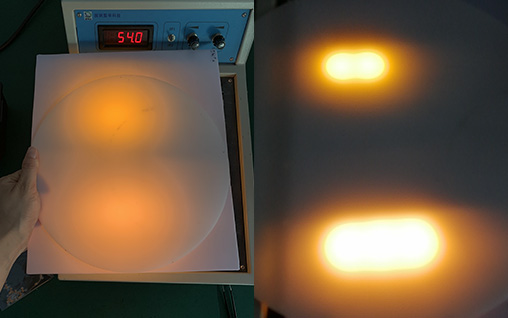

Additionally, we use a specialized frosted acrylic board to cross-check the color temperature with the expertise of our QC engineers, adding an extra layer of technical assurance.

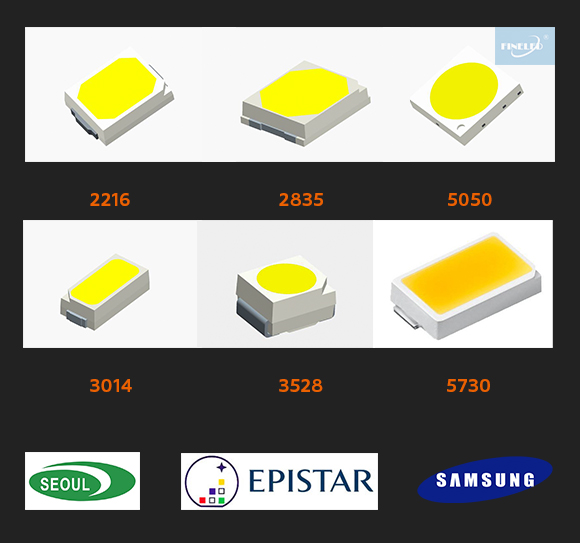

We use Epistar LEDs, manufactured in Taiwan since 1966, known for their professionalism and long lifespan of up to 50,000 hours.

Our LED strips also feature LEDs from Samsung and Seoul, including the 3535, 3030, and 5630 series.

It's important to note that while many budget LED strips may look similar to Epistar LEDs, they are often low-quality Chinese replicas with inferior internal components, resulting in a shorter lifespan. These LEDs are usually mounted on thin circuit boards with inadequate copper tracks for heat dissipation, further reducing their longevity.

Most low-cost LED strips are intended for short-term use, such as during festivals and holidays. They can experience issues like inconsistent color grading along the strip, leading to variations in white color temperature. Additionally, these cheaper LEDs may be more prone to damage and light attenuation over time.

For long-term use and professional installation, our LED strips are the much wider choice http://www.fine-led.com/index.php?s=/sys/list/12.html.

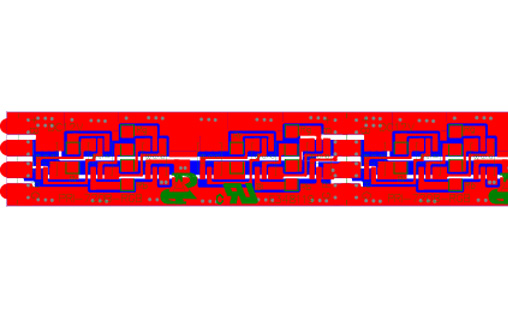

Featuring the stable and durable SMD 2835 for high brightness and output, our LED strip lights achieve an impressive light efficiency of up to 160 lumens per watt (Erp level E-D). The design ensures even light dispersion without spotting, making it ideal for high-quality linear LED lighting installations.

The product is specifically designed with 8 LEDs in series to achieve 160 lm/W (Erp level E). Available in white color options of 2700K, 3000K, 4000K, and 6500K with a high CRI, it is suitable for residential, television, retail, architectural, and commercial applications.

- 64 LEDs

- 144 LEDs

- 176 LEDs

- 240 LEDs Double Row

For our European clients, we have CE, RoHS, UKCA, BSCI, and ISO 9001:2015 certifications, and for our American and Canadian clients, we have FCC SDOC, UL, and cUL certifications.

SDCM stands for Standard Deviation Color Matching, synonymous with a "MacAdam ellipse." It measures the color consistency of LED lights with similar color temperatures. A common belief is that a lower MacAdam step indicates superior color consistency.

It's a common belief that a lower MacAdam step signifies superior color consistency matching.

The Color Rendering Index (CRI) is a metric used to evaluate how accurately a light source reveals the true colors of objects. High-CRI LED lighting refers to light-emitting diodes (LEDs) that offer a high CRI value. This metric quantifies a light source's ability to reproduce the colors of objects faithfully compared to an ideal or natural light source.

FINELED uses LED chips with a minimum Ra80 rating for our LED strip lights. Most of our LED chips typically show a Ra85+ rating when assessed using an integrating sphere machine. For specific projects, we can also provide Ra90 and Ra95 LED chips. We can supply a test report for each batch of our LED strip lights.

FINELED is dedicated to producing the highest quality LED strips by carefully selecting superior raw materials and implementing rigorous quality control procedures. Our quality control process includes IQC (Incoming Quality Control), IPQC (In-Process Quality Control), and FQC/OQC (Final/Outgoing Quality Control) checks to ensure exceptional production standards. For more insight into our production processes, please refer to our factory videos at http://www.fine-led.com/index.php?s=/sys/list/31.html. Here are some key aspects we consider:

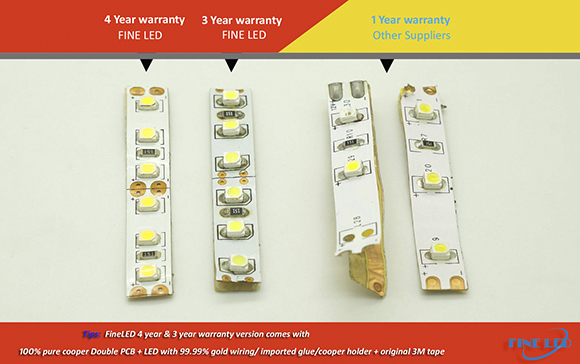

- PCB: We typically use 2Oz to 4Oz PCBs to facilitate better heat dissipation, which is vital for longevity. LED strips from FINELED are designed to have a basic lifespan of 50,000 hours, equivalent to six years of continuous use.

- LED: LED quality varies, and we understand there are differences in costs of up to 50% due to factors like internal wiring and gel quality. At FINELED, we use high-quality materials, including 99.99% pure gold wiring and reputable gel brands.

- Adhesive Tape: We use genuine 3M adhesive tape, ensuring the reliability of our products.

- Production Process and Quality Control: We maintain a strict and streamlined production process, from raw materials to finished products, and offer a 5-year warranty for continuous use.

- Color Consistency: Our LED strips maintain an impressive 99.99% color consistency.

- Bin Number: We ensure the same bin number for every order.

- CRI (Color Rendering Index): Our LED strips typically have a CRI of >85, with options for >90 and >95 Ra.

- SDCM (Standard Deviation Color Matching): We maintain a 3-step MacAdam standard for color consistency. These measures guarantee that FINELED produces high-quality LED strip lights, providing customers with reliable and consistent lighting solutions.